Injured or post-operative wounds need to be treated with a wound dressing to absorb excess exudate exudate from the wound so that the wound can heal quickly. However, the existing dressings have some shortcomings: the existing dressings can only protect the wound at the wound, but cannot protect the skin around the wound, especially for the wound surface at the joint, the existing dressing The dressing cannot protect the wound surface around the joint without affecting the movement of the joint, resulting in eczema on the skin around the joint due to long-term contact with the bedding or in a humid environment with permeate seepage. Even festering, not only affects the healing of wounds at the joints, but also greatly increases the pain of the injured.

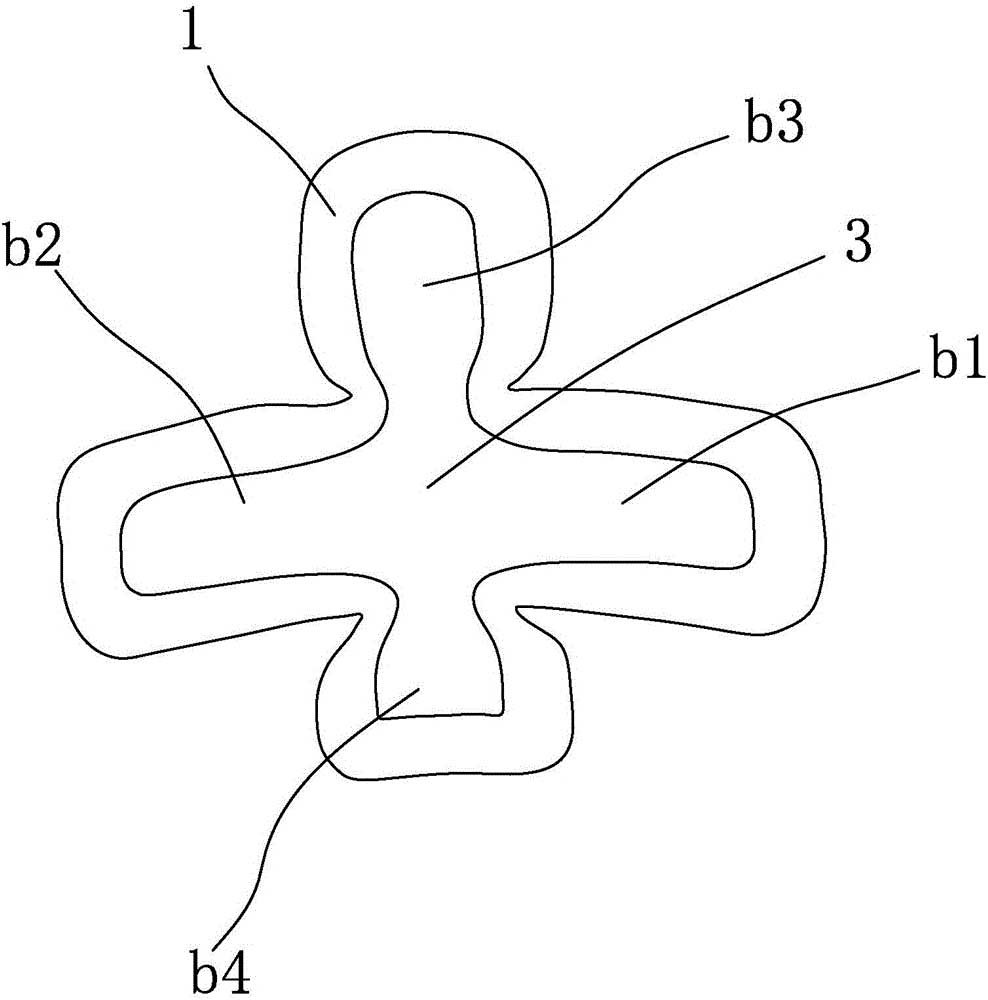

The purpose of the present utility model is to solve the above problems and provide a special-shaped silicone gel foam dressing, which can better protect the skin around the wound and relieve the pain of the patient. In order to achieve the above purpose, the present utility model adopts the following technical solutions: the special-shaped silicone gel foam dressing includes a dressing body, and is characterized in that, one side of the dressing body is provided with an adhesive layer in contact with the body surface, and the The dressing body includes a wound dressing that is laid on the wound surface at the joint, and the wound dressing is provided with a wound dressing that can wrap the skin around the wound at the joint after being folded in the direction close to the body surface when the wound dressing is laid on the wound at the joint. covered protective dressing. In the above-mentioned special-shaped silicone gel foam dressing, the protective dressing is connected with the wound dressing to form a "cross"-shaped dressing body with an integrated structure. In the above-mentioned special-shaped silicone gel foam dressing, the adhesive layer extends to the outside of the edges of the protective dressing and the wound dressing. In the above-mentioned special-shaped silicone gel foam dressing, the protective dressing includes a first protective dressing and a second protective dressing symmetrically arranged on the left and right sides of the wound dressing, and the upper and lower sides of the wound dressing are respectively A third protective dressing and a fourth protective dressing are provided. In the above-mentioned special-shaped silicone gel foam dressing, when the wound dressing is applied on the wound and the first protective dressing, the second protective dressing, the third protective dressing and the fourth protective dressing are respectively folded toward the body surface to When applied on the body surface, the first protective dressing, the second protective dressing, the third protective dressing and the fourth protective dressing can cover the skin around the wound at the joint. In the above-mentioned special-shaped silicone gel foam dressing, the connection between the third protective dressing and the fourth protective dressing and the wound dressing is a gathering structure with decreasing width. In the above-mentioned special-shaped silicone gel foam dressing, the shape and size of the first protective dressing are the same as those of the second protective dressing, and the length of the third protective dressing is greater than the length of the fourth protective dressing. In the above-mentioned special-shaped silicone gel foam dressing, a waterproof layer is provided on the surface of the dressing body on the side away from the adhesive layer. In the above-mentioned special-shaped silicone gel foam dressing, the edge of the waterproof layer overlaps with the edge of the adhesive layer, and the waterproof layer adopts a PU film layer. In the above-mentioned special-shaped silicone gel foam dressing, the side of the adhesive layer facing the skin is provided with two pieces of release paper capable of covering the surface, and the adjacent sides of the two pieces of third release paper overlap each other. Compared with the prior art, the advantage of the present invention is that the skin around the wound surface can be covered by a protective dressing without affecting the joint movement, thereby preventing eczema or even eczema on the skin around the wound surface at the joint. Festering can not only improve the healing speed of wounds at the joints, but also effectively reduce the pain of the injured. BRIEF DESCRIPTION OF THE DRAWINGS FIG. 1 is a structural diagram of a special-shaped silicone gel foam dressing provided by the present invention. Fig. 2 is a structural diagram of the dressing body provided by the present invention. 3 is a cross-sectional structural diagram of a special-shaped silicone gel foam dressing provided by the present invention. In the figure, dressing body a, adhesive layer 1, wound dressing 3, protective dressing b, first protective dressing b1, second protective dressing b2, third protective dressing b3, fourth protective dressing b4, gathering structure 4, waterproof layer 5 , Release paper 6. 1, 2, and 3, the special-shaped silicone gel foam dressing in this solution includes a dressing body a. One side of the dressing body a is provided with an adhesive layer 1 in contact with the body surface. The dressing body a Including a wound dressing 3 laid on the wound surface at the joint, the wound dressing 3 is provided with a wound dressing 3 that can cover the skin around the wound at the joint when the wound dressing 3 is laid on the wound surface and is folded in the direction close to the body surface. protective dressing b. This solution can cover the skin around the wound surface with the protective dressing b without affecting the joint movement, thereby preventing eczema or even ulceration of the skin around the wound surface at the joint, which can not only improve the healing speed of the wound at the joint, It also effectively relieves the pain of the injured. Further, the protective dressing b is connected with the wound dressing 3 to form a "cross"-shaped dressing body a with an integrated structure. The "cross"-shaped dressing body a designed according to the joint shape of the human body can be well applied to the treatment of wound surfaces at different joints such as the heel, knee or elbow. Further, the adhesive layer 1 extends to the outer edges of the protective dressing b and the wound dressing 3, which is convenient for sticking the protective dressing b and the wound dressing 3 on the skin surface more firmly. It has the advantages of non-sticky hair and no pain when torn off. At the same time, a number of ventilation holes are opened on the hydrogel layer, which can increase the air permeability of the hydrogel layer and facilitate the accelerated healing of wounds. Specifically, the protective dressing b includes a first protective dressing b1 and a second protective dressing b2 symmetrically arranged on the left and right sides of the wound dressing 3, and the upper and lower sides of the wound dressing 3 are respectively provided with a third protective dressing b3 and a second protective dressing b2. Fourth protective dressing b4. The first protective dressing b1 and the second protective dressing b2 can be symmetrically laid on both sides of the heel, thereby protecting the ankle joints on both sides of the heel and improving the healing ability of the wound. When the wound dressing 3 is applied on the wound and the first protective dressing b1 , the second protective dressing b2 , the third protective dressing b3 and the fourth protective dressing b4 are respectively folded toward the body surface to be applied on the body surface, the first protective dressing The dressing b1 , the second protective dressing b2 , the third protective dressing b3 and the fourth protective dressing b4 can cover the skin around the wound at the joint. Further, the connection between the third protective dressing b3 and the fourth protective dressing b4 and the wound dressing 3 is a gathered structure 4 with a decreasing width, and the gathered structure 4 is mainly designed for the dressing body a at the heel. The width of the Achilles tendon and the middle of the sole of the foot is small, and the gathering structure 4 can better make the third protective dressing b3 and the fourth protective dressing b4 fit with the sole of the foot and the Achilles tendon respectively, thereby improving the wrapping effect. Specifically, the shape and size of the first protective dressing b1 are the same as those of the second protective dressing b2, and the length of the third protective dressing b3 is greater than the length of the fourth protective dressing b4. Further, the surface of the dressing body a on the side away from the adhesive layer 1 is provided with a waterproof layer 5 . The edge of the waterproof layer 5 coincides with the edge of the adhesive layer 1, and the waterproof layer 5 adopts a PU film layer, so that the dressing body a has good waterproof performance, which can effectively prevent external water from penetrating into the wound surface through the dressing body when bathing or washing. Avoid the secondary infection of the wound surface, and block the healing speed of the wound. Further, the side of the adhesive layer 1 facing the skin is provided with two pieces of release paper 6 that can cover the surface, and the adjacent sides of the two pieces of the third release paper 6 overlap each other, which is convenient for attaching the dressing body a. aseptic operation, and can ensure that the stored dressing body a has aseptic safety performance. Working principle: tear off the release paper 6, first lay the wound dressing 3 on the wound surface of the joint, and then sequentially apply the first protective dressing b1, the second protective dressing b2, the third protective dressing b3 and the fourth protective dressing. b4 are respectively folded toward the body surface to be laid on the body surface. The first protective dressing b1, the second protective dressing b2, the third protective dressing b3 and the fourth protective dressing b4 can cover the skin around the wound at the joint. The skin around the wound surface can be covered by the protective dressing b without affecting the joint movement, thereby preventing eczema or even ulceration of the skin around the wound surface at the joint. The first protective dressing b1 and the second protective dressing The b2 can be symmetrically laid on both sides of the heel, thereby protecting the ankle joints on both sides of the heel, which can not only improve the healing speed of the wound at the joint, but also effectively relieve the pain of the injured. The specific embodiments described herein are merely illustrative of the spirit of the present invention. Those skilled in the art of the present invention can make various modifications or supplements to the described specific embodiments or replace them in similar ways, but will not deviate from the spirit of the present invention or go beyond the appended claims the defined range. Although the dressing body a, the adhesive layer 1, the wound dressing 3, the protective dressing b, the first protective dressing b1, the second protective dressing b2, the third protective dressing b3, the fourth protective dressing b4, and the gathering structure 4 are used more in this paper , waterproof layer 5, release paper 6 and other terms, but do not exclude the possibility of using other terms. These terms are only used to describe and explain the essence of the present invention more conveniently, and it is contrary to the spirit of the present invention to interpret them as any kind of additional limitations.

Technical Features:

1. A special-shaped silicone gel foam dressing, comprising a dressing body (a), wherein one side of the dressing body (a) is provided with an adhesive layer (1) in contact with the body surface, and the dressing body (a) comprising a wound dressing (3) laid on the wound surface at the joint, the wound dressing (3) is provided with a wound dressing (3) that is folded toward the body surface when the wound dressing (3) is laid on the wound surface at the joint A protective dressing (b) capable of covering the skin around the wound surface at the joint.

2 . The special-shaped silicone gel foam dressing according to claim 1 , wherein the protective dressing (b) is connected with the wound dressing (3) to form a “cross”-shaped dressing body (a) with an integrated structure.

3. The special-shaped silicone gel foam dressing according to claim 2, wherein the adhesive layer (1) extends to the outer edges of the protective dressing (b) and the wound dressing (3).

4. The special-shaped silicone gel foam dressing according to claim 3, wherein the protective dressing (b) comprises a first protective dressing (b1) symmetrically arranged on the left and right sides of the wound dressing (3). and a second protective dressing (b2), the upper and lower sides of the wound dressing (3) are respectively provided with a third protective dressing (b3) and a fourth protective dressing (b4).

5. The special-shaped silicone gel foam dressing according to claim 4, characterized in that: when the wound dressing (3) is applied to the wound and the first protective dressing (b1), the second protective dressing (b2), When the third protective dressing (b3) and the fourth protective dressing (b4) are respectively folded toward the body surface to be laid on the body surface, the first protective dressing (b1), the second protective dressing (b2), the third protective dressing (b3) and the fourth protective dressing (b4) can cover the skin around the wound at the joint.

6. The special-shaped silicone gel foam dressing according to claim 5, characterized in that: the joints of the third protective dressing (b3) and the fourth protective dressing (b4) and the wound dressing (3) are of decreasing width The retractable structure (4).

7. The special-shaped silicone gel foam dressing according to claim 6, characterized in that: the shape and size of the first protective dressing (b1) are the same as the second protective dressing (b2), and the third protective dressing (b2) The length of the dressing (b3) is greater than the length of the fourth protective dressing (b4).

8. The special-shaped silicone gel foam dressing according to any one of claims 1 to 7, characterized in that: the surface of the dressing body (a) away from the adhesive layer (1) is provided with a waterproof layer (5). ).

9. The special-shaped silicone gel foam dressing according to claim 8, wherein the edge of the waterproof layer (5) coincides with the edge of the adhesive layer (1), and the waterproof layer (5) is made of PU film layer.

10. The special-shaped silicone gel

foam dressing according to claim 9, characterized in that: the side of the adhesive layer (1) facing the skin is provided with two pieces of release paper (6) capable of covering the side, and The adjacent sides of the two third release papers (6) are overlapped with each other.

Technical summary

The utility model provides a special-shaped silicone gel foam dressing, comprising a dressing body, characterized in that, one side of the dressing body is provided with an adhesive layer contacting with the body surface, and the dressing body comprises a dressing body which is laid on a joint wound. The wound dressing is provided with a protective dressing capable of covering the skin around the wound surface of the joint when the

wound dressing is applied to the wound surface of the joint and folded toward the body surface. The utility model can better protect the skin around the wound and relieve the pain of the patient.

Technical research and development personnel: Wu Kangping

Protected technology user: Zhejiang Longterm Medical Technology Co., Ltd.

Document number: 201620300313

Technology R&D Day: 2016.04.11

Technical release date: 2016.11.23